- info@pennair.com

- 888-631-7638

- Service Counter: 717-840-1600

March 31, 2021 // 1 minute read

Customized adhesive gripper for your application

The bionically inspired ADHESO gripper technology is based on the principle of adhesion and uses intermolecularly acting Van der Waals forces to handle various workpieces.

The advantages of ADHESO gripper technology are revolutionary:

SCHUNK’s application experts take advantage of these benefits and develop customer-specific adhesive grippers with ADHESO gripper technology. Due to the high variability of the adhesive structures, grippers with ADHESO technology can be directly tailored to the requirements of your application.

Inspired by Nature

The gripper technology of ADHESO grippers is based on an adhesive system modeled on nature. The adhesive forces used by animals such as geckos for locomotion are now being utilized by SCHUNK for use in handling applications in the most diverse of fields.

Material & Surface

SCHUNK grippers with ADHESO gripper technology have a distinctive surface architecture made of special polymers. The result is an extremely fine leg-like structure that adheres to a wide variety of materials and objects without leaving a residue. The scalability options and use of different material characteristics allows the adhesive structure to be adapted to different workpieces and surfaces. This makes grippers with ADHESO technology easy to customize for the most diverse workpieces and applications.

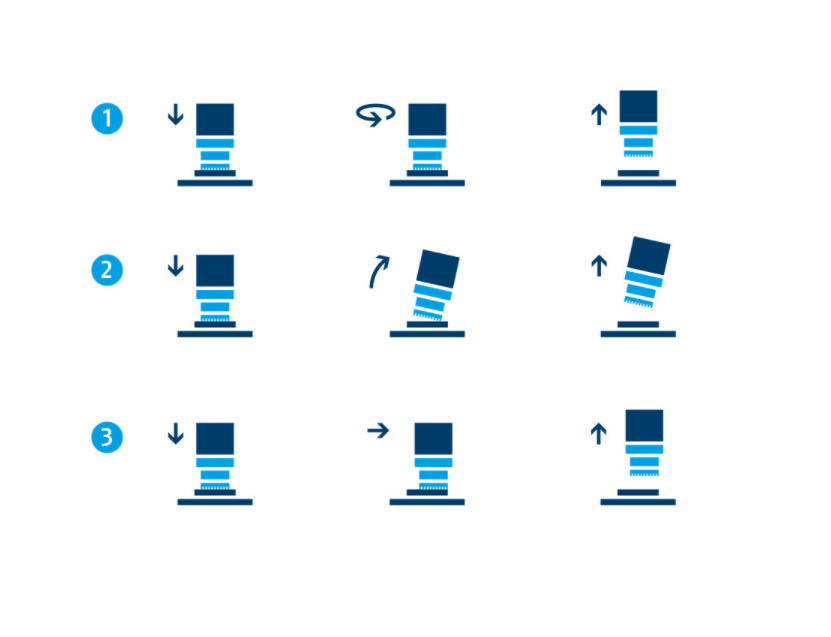

Gripping Process

SCHUNK grippers with ADHESO gripper technology have a distinctive surface architecture made of special polymers. The result is an extremely fine leg-like structure that adheres to a wide variety of materials and objects without leaving a residue. The scalability options and use of different material characteristics allows the adhesive structure to be adapted to different workpieces and surfaces. This makes grippers with ADHESO technology easy to customize for the most diverse workpieces and applications.

Adhesive grippers without energy needs

The gripper solutions that are possible with ADHESO are as diverse as the applications themselves. By varying the material, topography and miniaturization, the gripper can be individually tailored to the different requirements of your application.

SCHUNK offers four standardized ADHESO gripper pad sizes with matching ISO flange adapter, which can already be used to implement a large number of gripper applications quickly and cost-effectively. On request, SCHUNK can also supply a customized ADHESO gripping solution directly tailored to your application.

Benefits from the advantage of ADHESO gripper technology now:

Grippers with ADHESO technology in laboratory automation, technology, medical and pharmaceutical industry.

Containers, syringes and other medical objects made of plastic and glass often have very smooth surfaces and are therefore ideally suited for gripping with SCHUNK ADHESO. The particle-free and energy-efficient gripping process allows the ADHESO grippers to be used without any issue even in hygienically sensitive environments. This technology makes it possible to grip without the need for additional energy and without leaving any residue.

Grippers with ADHESO technology in the electronics industry.

Whether for the assembly of printed circuit boards or for gripping complete wafers or circuit boards: SCHUNK ADHESO grippers are ideal for a variety of applications in the electronics industry. Due to the unique ADHESO gripping technology, there are no mechanical pulses acting during the gripping process. That is why SCHUNK ADHESO offers the optimum solution, without causing any residue or particle emission.

We’re looking forward to helping you. Whether you have questions about products, services, or a demo, our team is ready to help.

Fields with an asterisk* are required. This information allows us to better assist you.

Your information will not be shared beyond our organization. The information collected is simply used to better assist you. Please visit our Privacy Policy to learn more.

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/