- info@pennair.com

- 888-631-7638

- Service Counter: 717-840-1600

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.

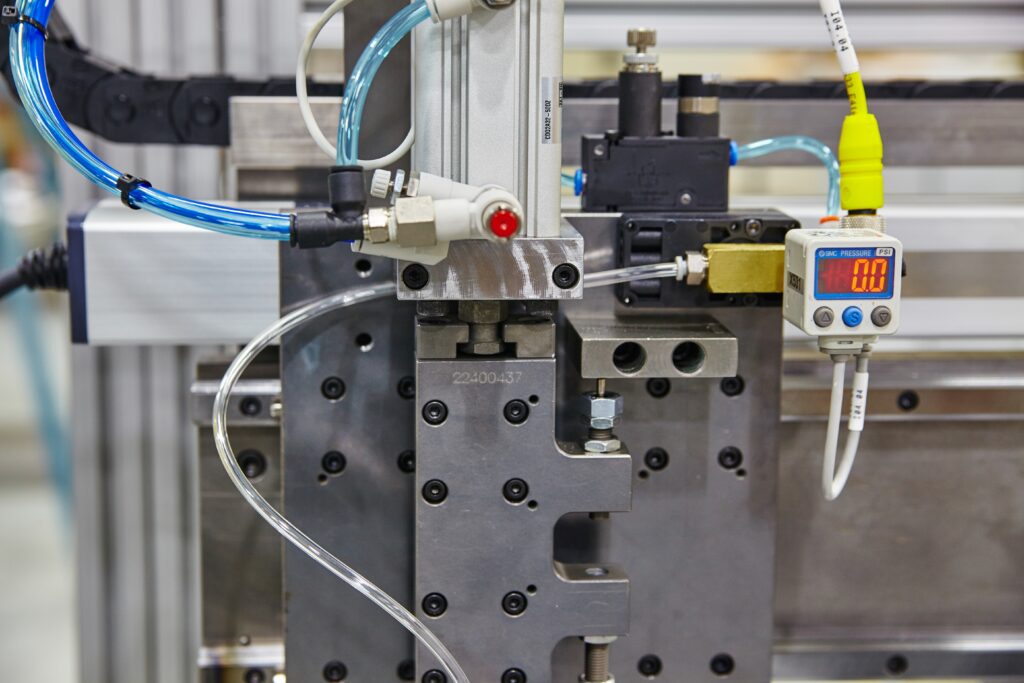

Pneumatic systems are essential in industrial automation, offering efficient and reliable motion control. However, like any system, they can develop issues that affect performance, cause downtime, and lead to costly repairs. Understanding common pneumatic failures and how to troubleshoot them can help keep equipment operating at peak efficiency.

Symptoms:

Possible Causes & Fixes:

Symptoms:

Possible Causes & Fixes:

Low air supply or restricted flow can prevent actuators from functioning properly. Ensure the air supply meets system requirements, and inspect tubing for kinks, obstructions, or restrictions.

Valve failure or malfunction can block air from reaching the actuators. Inspect directional control valves for signs of wear, contamination, or sticking. Clean or replace faulty valves as needed.

Undersized components may limit actuator performance. If actuators move too slowly, consider upgrading to a larger cylinder or increasing airflow capacity.

Symptoms:

Possible Causes & Fixes:

Inadequate air drying can lead to excessive moisture in the system. Ensure an appropriate air dryer is installed and operating correctly. Regularly drain moisture traps to prevent water buildup.

Faulty or overloaded air dryers may not be functioning effectively. Inspect air dryers and replace them if they are not removing moisture properly.

High ambient humidity can introduce additional moisture. Use moisture separators, desiccant dryers, or refrigerated air dryers to manage humidity levels.

Symptoms:

Possible Causes & Fixes:

Turbulence from incorrect airflow or pressure settings can cause noise. Check and adjust pressure regulators and flow controls to stabilize airflow.

Excessive wear in moving parts can create knocking or rattling sounds. Inspect actuators, valves, and seals for wear, and replace any worn components.

Loose or misaligned components can lead to excessive vibration. Secure all fittings, hoses, and brackets to minimize movement and noise.

Symptoms:

Possible Causes & Fixes:

Control valve malfunctions can lead to inconsistent system performance. Check solenoid valves for power and function. Clean or replace valves that are sticking or not operating correctly.

Air contamination or inadequate lubrication can cause system inefficiencies. Use clean, dry air and ensure lubricators are properly set to maintain optimal lubrication levels.

Incorrect flow rate adjustments can impact performance. Fine-tune flow control valves to optimize actuator speed and efficiency.

To prevent pneumatic system failures and improve longevity:

If your pneumatic system is experiencing ongoing issues, our team is here to help. Contact us for expert support, replacement parts, and customized solutions to keep your equipment running smoothly.

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/