- info@pennair.com

- 888-631-7638

- Service Counter: 717-840-1600

Transforming the conveyor automation since 1966

November 22, 2021 // 1 minute read

For years, Dorner conveyor experts have been developing and producing cutting-edge systems for assembly and industrial needs. These precision move pallet systems are flexible, accurate, versatile, and easy to use. The unique design behind these systems gives them a competitive advantage when it comes to increasing efficiency and decreasing downtime. Their automated systems are proven to reduce costs while saving time and resources with proper configuration.

Don’t leave conveyor automation to chance. Take control with Dorner’s pallet systems and precision move technology in automation. There are many benefits to applying their assembly and industrial automation conveyor technology, such as:

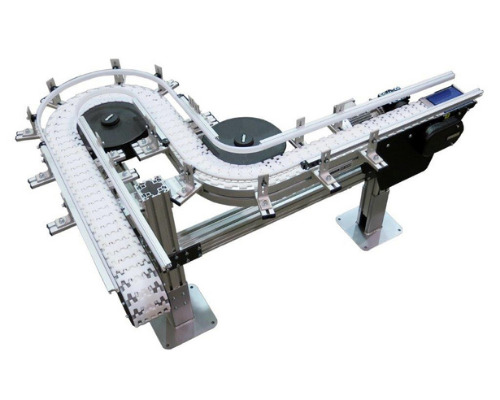

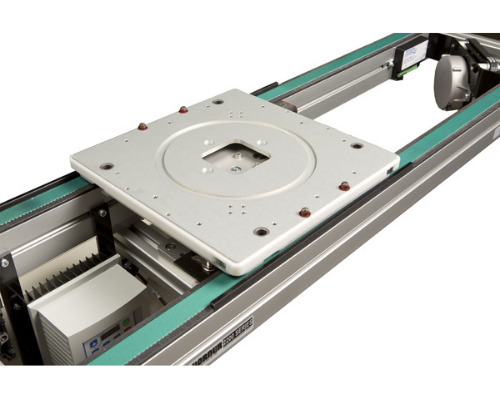

The assembly automation market has driven us to create machines that drive automation. The 2200 Series Precision Move Pallet System conveyor and our FlexMove Pallet Systems are advanced in pallet traffic management and are specifically designed to increase efficiency, reduce downtime in automation processes, and provide accurate conveying.

The pallet systems provide unique flexibility with extended benefits; line configurations range from high load capacities to quick belt changes and cleanroom certifications. Get accurate positioning and routing with our precision move and pallet systems, designed to streamline assembly processes and inspections.

The systems come in kits for those interested in customizing their installation. With our D-Tools configuration process, you can control each step of the design process from choosing materials to selecting a layout.

With years of experience, we’re ready to help even if your line faces unique challenges due to difficult or unwieldy product packaging, assembly, industrial, sanitation, incline, or product inspection challenges. We offer a wide selection of product and conveyor solutions that includes: product repositioning conveyor technology, magnetic belt for easy line transportation, or smaller conveyors that work best for line integration. When it comes to fitting your conveyor needs, Dorner has the solution.

Dorner has engineered numerous conveyor automation innovations such as:

By transitioning to an updated conveyor, your line could begin operating with an efficiency of 90%. From mechanical design to installation and project management, Dorner Conveyor has the experience and knowledge to work with you to create efficient workflow automation.

We’re looking forward to helping you. Whether you have questions about products, services, or a demo, our team is ready to help.

Fields with an asterisk* are required. This information allows us to better assist you.

Your information will not be shared beyond our organization. The information collected is simply used to better assist you. Please visit our Privacy Policy to learn more.

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/