- info@pennair.com

- 888-631-7638

- Service Counter: 717-840-1600

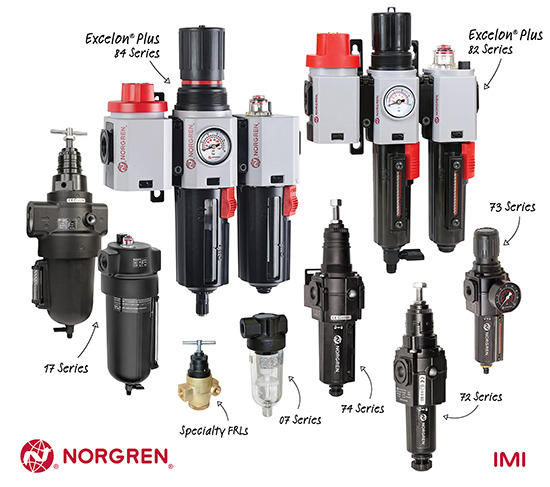

Compressed air is used in almost every industry, from building cars to opening bus doors, from food processing to general factory automation. IMI’s world class air preparation provides clean controlled compressed air to these industries and more.

Excelon® Plus is the latest generation of IMI air preparation equipment developed to meet the needs of today’s customers. It offers exceptional performance, is compact and lightweight with no compromise on robustness, and is suitable for all industrial applications.

PennAir helps our customers KICK@$$ by having IMI’s Excelon® Plus available and in stock in our warehouse. Contact our Customer Service Team for a quote and delivery details.

With safety in mind, Excelon® Plus has been designed with tamper resistant features built in as a standard, with padlock features on both the shut-off valves and regulator. A rotating safety shut-off valve makes it easy to isolate the system with no reduction in performance. A unique double safety bowl lock, with an audible bowl clip plus a safety detent when pressurized, makes it impossible to remove the bowl when in use.

New soft start dump and control valves enhance safety and application control within Excelon® Plus systems. Soft start dump valves allow downstream pressure to gradually increase on initial start up, before fully opening to deliver line pressure. The dump function allows the system to be exhausted quickly when required, particularly in the event of a power failure or emergency stop. Electrically operated control valves provide improved user experience compared to similar manually operated valves.

With the new safety and functionality features and a compact and lightweight design with no compromise on robustness, Excelon Plus helps keep customers’ machines running smoothly.

Correctly specified, well maintained air preparation is essential to the effective operation of any compressed air system. Whether a large factory air supply, or a small high-speed processing machine air preparation equipment are the tools to make it safe, optimize the running costs and keep the machines running.

We’re looking forward to helping you. Whether you have questions about products, services, or a demo, our team is ready to help.

Fields with an asterisk* are required. This information allows us to better assist you.

Your information will not be shared beyond our organization. The information collected is simply used to better assist you. Please visit our Privacy Policy to learn more.

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/