- info@pennair.com

- 888-631-7638

- Service Counter: 717-840-1600

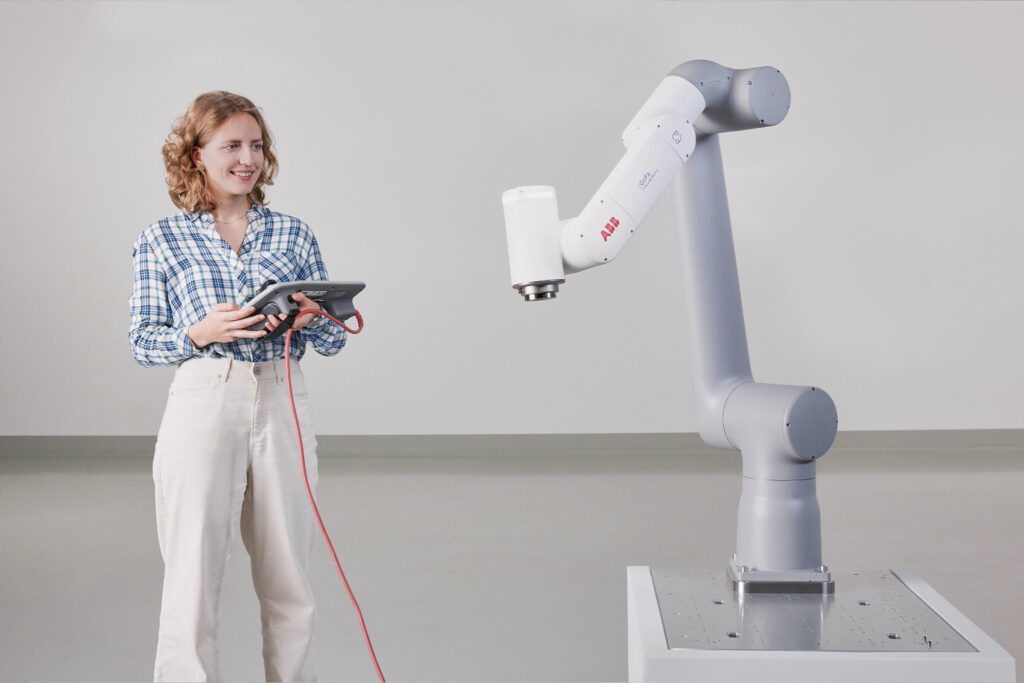

Accelerate and elevate your business with GoFa’s unparalleled speed, safety, and user-friendliness. GoFa’s advanced capabilities allow for safe operation alongside humans without the need for cumbersome barriers, offering unparalleled flexibility and efficiency. This collaboration between robots and humans enhances task execution without compromising safety or productivity.

The ABB GoFa excels in delivering unparalleled precision with every weld. Equipped with advanced sensors and motion control technology, it ensures accurate positioning, smooth movement, and optimal torch control. This robotic welding powerhouse effortlessly handles complex joint configurations, tight spaces, and challenging angles, enabling flawless welds even in the most demanding applications.

GoFa is engineered to manage payloads up to 5kg, 10kg, and 12kg, equipped with torque sensors in all six joints for exceptional control and safety. These features are designed to minimize injury risk by instantly stopping GoFa if it detects any contact with a human, ensuring a safer collaborative environment.

The setup and configuration process is streamlined through user-friendly, graphical applications available directly on the FlexPendant, allowing for quick and intuitive robot movement through lead-through techniques.

GoFa offers a maximum Tool Center Point (TCP) speed of up to 2.2 m/s,* faster than other cobots in its class. GoFa can perform more operations in a set period than competing robots.

Popular applications include, but are not limited to: Material Handling, Machine Tending, Assembly, Picking & Packaging, and Screwdriving.

Product manual CRB 15000, GoFa

Product manual for CRB 15000, GoFa. This document contains instructions for installation, maintenance, and repair of the manipulator.

Product specification – Robot stopping distances according to ISO 10218-1

This specification contains stopping distances and times for category 0 and category 1 stops, as required by EN ISO 10218-1 Annex B. This specification should be used when calculating the safe distance in applying safeguarding devices.

Product specification CRB 150000, GoFa

Product specification for CRB 15000, GoFa. This document contains information about available sales options for the manipulator.

Operating manual – Robot Control Mate

Product specification for CRB 15000, GoFa. This document contains information about available sales options for the manipulator.

Robotics product range brochure 2023 robots overview digital PDF global – 12 pages

Added new robots including IRB 1010, IRB 365, IRB 5710, IRB 5720, IRB 920, CRB 1300

Collaborative Robot System Certification CRB 15000

No summary available.

CRB 15000 Certificate of cleanroom for SGS

No summary available

Collaborative Robot System Certification CRB 15000

No summary available

Product specification – Robot stopping distances according to ISO 10218-1

This specification contains stopping distances and times for category 0 and category 1 stops, as required by EN ISO 10218-1 Annex B. This specification should be used when calculating the safe distance in applying safeguarding devices.

Product specification CRB 15000, GoFa

Summary: Product specification for CRB 15000, GoFa. This document contains information about available sales options for the manipulator.

Ready to up your production game with ABB’s GoFa CRB 15000 cobot? PennAir’s sister brand, Valley Fluid Components, is here to be your trusted partner. Whether you’re looking to enhance your automation capabilities or troubleshoot any issues, their team is fully equipped and ready to assist you in the Greater Virginia area.

We’re looking forward to helping you. Whether you have questions about products, services, or a demo, our team is ready to help.

Fields with an asterisk* are required. This information allows us to better assist you.

Your information will not be shared beyond our organization. The information collected is simply used to better assist you. Please visit our Privacy Policy to learn more.

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/