- info@pennair.com

- 888-631-7638

- Service Counter: 717-840-1600

Manufacturer of pneumatic valves and components engineered to outperform and outlast.

August 26, 2022 // 1 minute read

Real World Reliability

VERSA’s Diagnostic Feedback Options offer the same tried-and-true valves they have always provided with added intelligence capability. With the addition of key modular components, they can open the valve to strategic sensors.

Combined with their extensive valve options and the ever-expanding IIoT technologies, this opens a blank canvas for users to engineer an endless variety of intelligent systems.

When a spool valve’s solenoid is energized, it lifts a poppet, and air pressure is allowed through to the piston, providing the force to shift the valve.

The field-proven Remote Sensor Port option opens a 1/8” NPT port inside the pilot chamber. As the poppet lifts, the sensor port also receives pressure. This port can be fitted with pressure sensors of various kinds for a wealth of diagnostic feedback information focused on the solenoid operation.

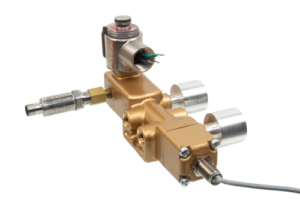

Remote Sensor Port (-20)

When a spool valve’s solenoid is energized, it lifts a poppet, and air pressure is allowed through to the piston, providing the force to shift the valve.

The field-proven Remote Sensor Port option opens a 1/8” NPT port inside the pilot chamber. As the poppet lifts, the sensor port also receives pressure. This port can be fitted with various pressure sensors for a wealth of diagnostic feedback information focused on the solenoid operation.

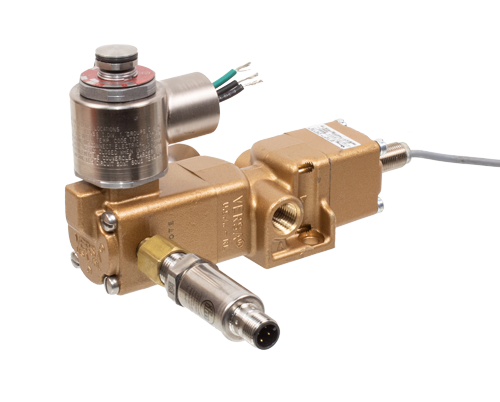

Spring Cap Sensor Port (-407)

In some cases, theoretical feedback on the spool position isn’t enough. For those applications, VERSA offers a spring cap sensor port. The design provides an M12 threaded spring cap to allow proximity sensors direct contact with the spool.

In many Emergency Shut Down (ESD) applications, a control solenoid may not be cycled for long periods. While VERSA valves are designed for the toughest environments, it’s always important to cycle and test in critical safety applications to ensure a working system before an emergency. Many problems, especially ingress issues affecting the spool, will remain undetected unless the valve is cycled. While every application presents different factors, it’s statistically proven that cycling your valve more often leads to less failure in the field.

VERSA’s Diagnostic Feedback Options can be used to build a Smart Exercise & Bypass Circuit, allowing for process monitoring, automated cycling, and diagnostic feedback from your control solenoids without cycling the ESD valve. Advantages to this design include:

Equipping valves with sensory feedback adds diagnostic intelligence to an already highly reliable system.

Simple programming and controller integration allows for automated bypass activation and cycle tests. Signals from installed sensors will confirm solenoid health and spool shift and report failure modes.

While smart circuit packages exist in the market, the VERSA advantage comes in flexibility and high flow rates. Our modular design and fully ported valves allow for a mix of functionality, safety, high flow, and reliability options that are unmatched in the market.

REAL WORLD CHALLENGE:

According to the EPA, natural gas and petroleum systems are the second-largest sources of methane emissions in the US. With new calls to reduce methane emissions emerging all the time, it’s important to understand how this affects system testing.

Partial stroke testing of ESD systems can release gas emissions into the atmosphere, limiting the frequency in which operators can run these tests and simultaneously making tests more valuable.

VERSA SOLUTION:

It’s more important than ever to select your solenoid valves properly for reliability. By adopting a Smart Exercise and Bypass Circuit system from VERSA, users will have the ability to monitor and test their control solenoids regularly. This can be done between partial valve stroke tests to avoid long stretches of valve inactivity.

We’re looking forward to helping you. Whether you have questions about products, services, or a demo, our team is ready to help.

Fields with an asterisk* are required. This information allows us to better assist you.

Your information will not be shared beyond our organization. The information collected is simply used to better assist you. Please visit our Privacy Policy to learn more.

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/