- info@pennair.com

- 888-631-7638

- Service Counter: 717-840-1600

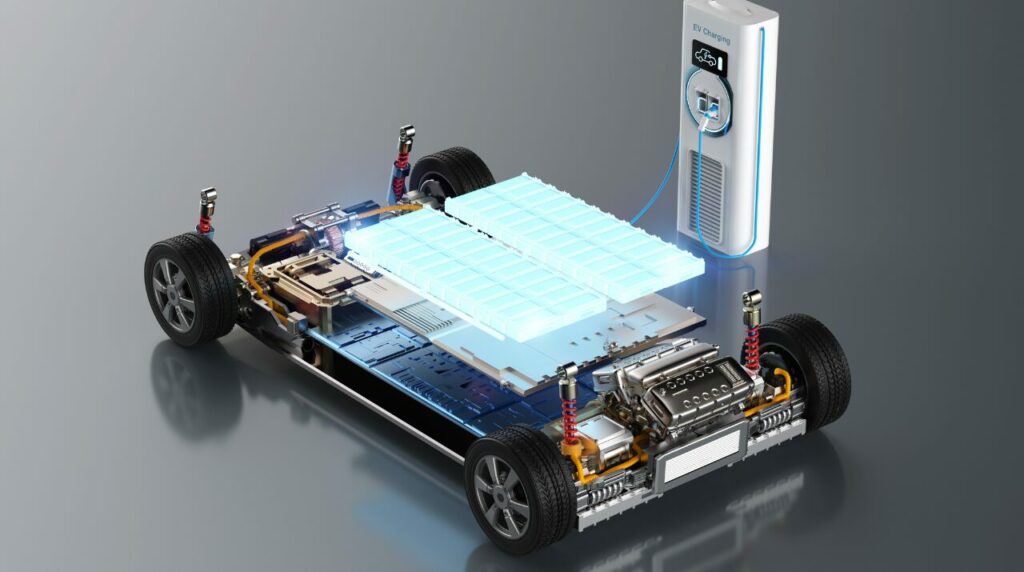

The automotive industry is rapidly shifting towards electric vehicles, driving significant changes in manufacturing processes. This transformation demands the adoption of flexible, intelligent, and energy-efficient production technologies. As a distributor of Festo, PennAir is at the forefront of this revolution, serving customers in Pennsylvania, Maryland, New Jersey, and Delaware.

Electric vehicles (EVs) are becoming increasingly popular due to stringent emission regulations, advancements in battery technology, and rising consumer demand for sustainable transportation. This shift from internal combustion engines to electric drivetrains requires innovative manufacturing approaches to remain competitive.

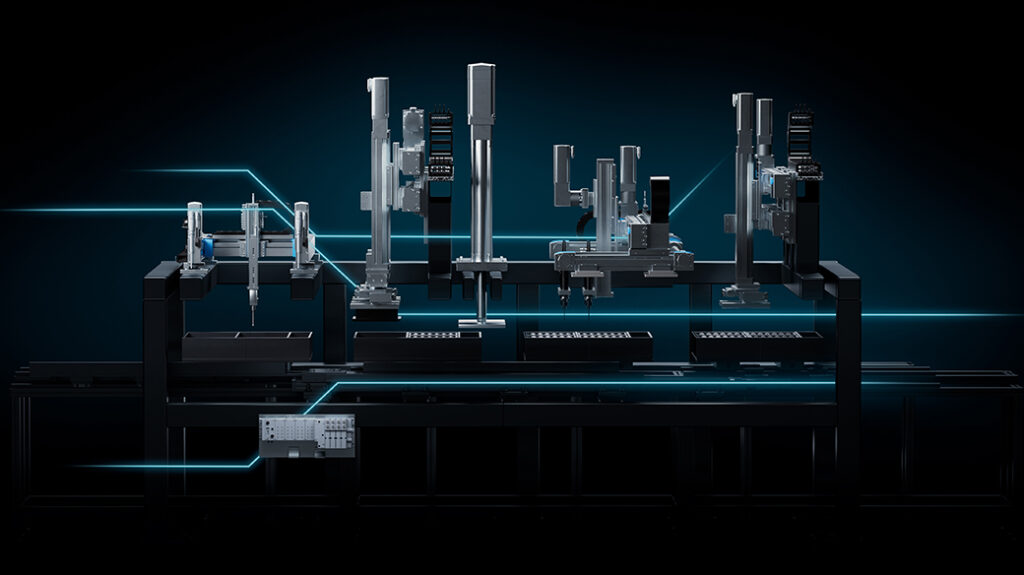

Festo understands the challenges faced by battery manufacturers in the Mid-Atlantic region. With a global presence and local expertise, Festo provides comprehensive support for battery production, ensuring efficiency, reliability, and flexibility in your processes.

From handling raw materials to testing modules and packs, and even recycling, Festo offers tailored solutions to meet requirements. Their automation technologies enhance production consistency, reduce waste, and improve overall efficiency.

The initial stage of battery production involves the precise handling of raw materials such as lithium, cobalt, and nickel. Festo’s automation solutions ensure accurate dosing, mixing, and transport of these materials, reducing waste and improving production consistency.

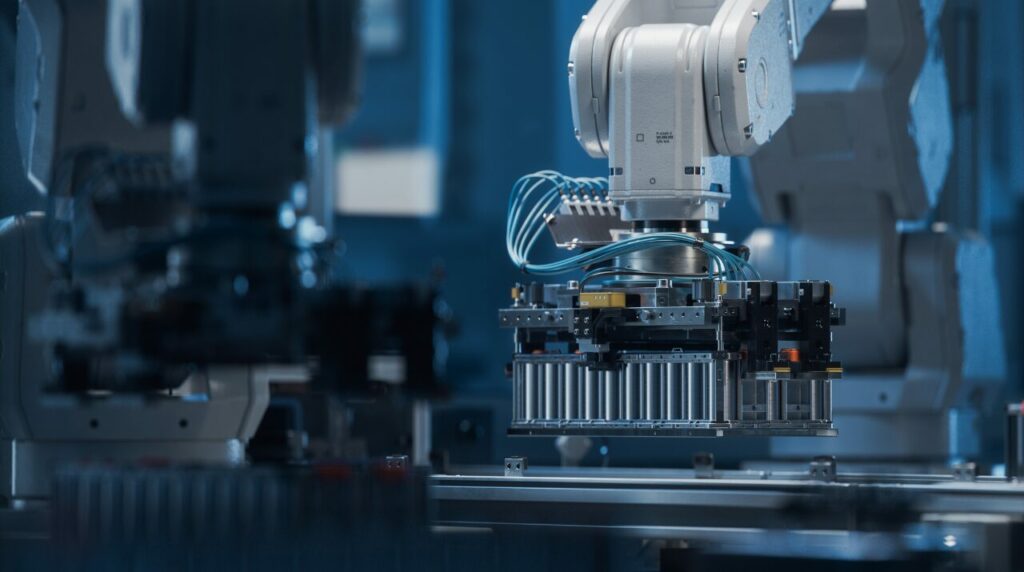

Battery cell assembly involves assembling extremely expensive and dangerous electrochemical components. Festo offers perfectly matched solutions for handling technology, such as sturdy, reliable, and precise gripping of battery cells using vacuum generators and adaptive gripper fingers.

Ensuring the reliability and performance of battery modules and packs is essential. Festo provides comprehensive testing solutions that enable manufacturers to conduct thorough quality checks, ensuring each battery meets the required specifications. Leak testing and thermal paste application are critical processes, supported by Festo’s precise dispensing and pressing systems.

As the demand for batteries grows, so does the need for effective recycling solutions. Festo’s automation technologies facilitate the efficient disassembly and recycling of batteries, helping manufacturers reduce their environmental impact and recover valuable materials.

Festo’s components are designed to be copper-free, zinc-free, and dry-room-compatible, ensuring they meet the stringent requirements of battery production environments. They continually invest in research and development to enhance energy efficiency and reduce waste, supporting sustainable manufacturing practices.

As a distributor of Festo, PennAir is dedicated to providing top-notch automation solutions to manufacturers in Pennsylvania, Maryland, New Jersey, and Delaware. Our partnership with Festo ensures access to cutting-edge technologies and unparalleled support, helping you navigate the complexities of battery production.

The transition to electric vehicles presents both challenges and opportunities for battery manufacturers in the Mid-Atlantic region. By partnering with Festo and PennAir, you can leverage our expertise and innovative capabilities to stay ahead in this evolving market.

Electromobility Brochure Download

Electrification in the automotive industry is gathering pace and redefining mobility. The use of energy-efficient drive solutions is opening up more and more opportunities for future-oriented, green and economical vehicle concepts.

A: Festo’s components are copper-free, zinc-free, and dry-room-compatible, ensuring they meet the stringent requirements of battery production environments

A: Festo invests in R&D to create energy-efficient and waste-reducing solutions, and provides technologies for efficient battery recycling

A: Yes, Festo’s smart automation systems are designed to be compatible with Industry 4.0 trends, offering real-time monitoring, analytics, and predictive maintenance

A: Festo provides solutions for raw material handling, core module assembly, module and pack testing, and recycling

Ready to up your production game with ABB’s Cobot Arc Welding Package? PennAir’s sister brand, Valley Fluid Components, is here to be your trusted partner. Whether you’re looking to enhance your automation capabilities or troubleshoot any issues, their team is fully equipped and ready to assist you in the Greater Virginia area.

We’re looking forward to helping you. Whether you have questions about products, services, or a demo, our team is ready to help.

Fields with an asterisk* are required. This information allows us to better assist you.

Your information will not be shared beyond our organization. The information collected is simply used to better assist you. Please visit our Privacy Policy to learn more.

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/