CVL Technical Sales, PennAir’s sister brand since 2024, will be integrated into PennAir on December 19 – same team, stronger capabilities.

- info@pennair.com

- 888-631-7638

- Service Counter: 717-840-1600

CVL Technical Sales, PennAir’s sister brand since 2024, will be integrated into PennAir on December 19 – same team, stronger capabilities.

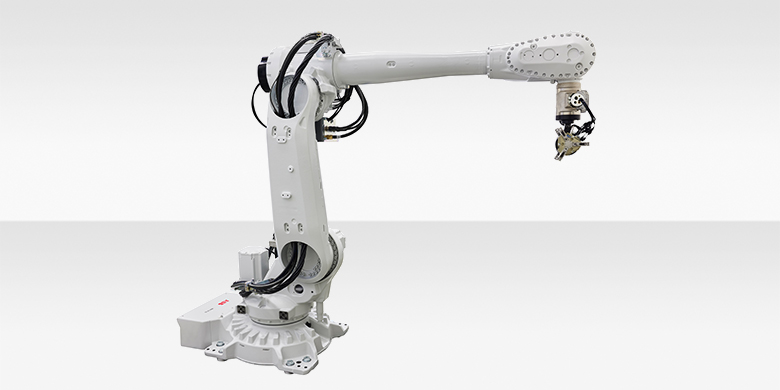

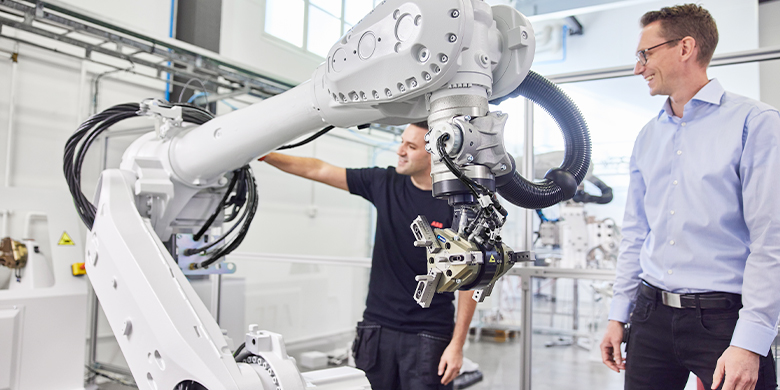

ABB is expanding its large-size robot portfolio with IRB 5710, offering faster, more robust, and accurate performance. The IRB 5710 is available in four variants, presenting a choice of options for payload from 70kg to 110kg, reach from 2.3m to 2.7m.

IRB 5710 is ideal for use in material handling, machine tending, and high precision assembly applications in the Electric Vehicle battery production, automotive, and the general industries.

Up to 25% faster than other robots.

High accuracy and position repeatability 0.04-0.05mm enables high quality manufacturing.

Integrated DressPack eliminated swinging cables, increases uptime and reduces maintenance costs.

3 multiple mounting options maximize production design flexibility.

Thanks to the robot’s robust design and OmniCore V250XT controller’s motion control, the IRB 5710 provides improved speed and accuracy to help increase productivity. IRB 5710 is faster than other robots in its class and up to 25 percent faster than IRB 6700 and IRB 6620, enabling more products to be manufactured in less time.

With the excellent position repeatability (0.04-0.05mm),

path repeatability (0.12-0.16mm), and path accuracy (1-1.2 mm), IRB 5710 is more accurate than other robots, enabling the highest levels of manufacturing quality to be achieved.

IRB 5710-110/2.3

IRB 5710-90/2.7

IRB 5710-90/2.3 LID

IRB 5710-70/2.7 LID

By integrating cabling within the body of the robot, ABB’s unique LeanID Integrated DressPack reduces the problem of swinging cables that can cause wear and tear, reducing downtime and maintenance cost. LeanID makes it easier to program and simulate with predictable cable movements in RobotStudio®.

IRB 5710 has 3 multiple mounting options, including floor, angled, inverted for maximum production layout design flexibility.

The smaller turning radius enables compact application cells, saves floor space, allows increased robot density.

Suitable for a wide range of production tasks, including spot welding, cutting, material handling, machine tending, assembly, plastic molding, metal casting, cleaning, and spraying applications, as well as specific operations in EV manufacturing such as battery module picking and placing.

Robotics Product Range brochure

Summary: new robots including IRB 1090, IRB 6710, IRB 6720, IRB 6730, IRB 6740, IRB 930.

IRB 5710, OmniCore Product specification

No summary available.

Ready to up your production game with ABB’s IRB 5710? PennAir’s sister brand, Valley Fluid Components, is here to be your trusted partner. Whether you’re looking to enhance your automation capabilities or troubleshoot any issues, their team is fully equipped and ready to assist you in the Greater Virginia area.

We’re looking forward to helping you. Whether you have questions about products, services, or a demo, our team is ready to help.

Fields with an asterisk* are required. This information allows us to better assist you.

Your information will not be shared beyond our organization. The information collected is simply used to better assist you. Please visit our Privacy Policy to learn more.

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/