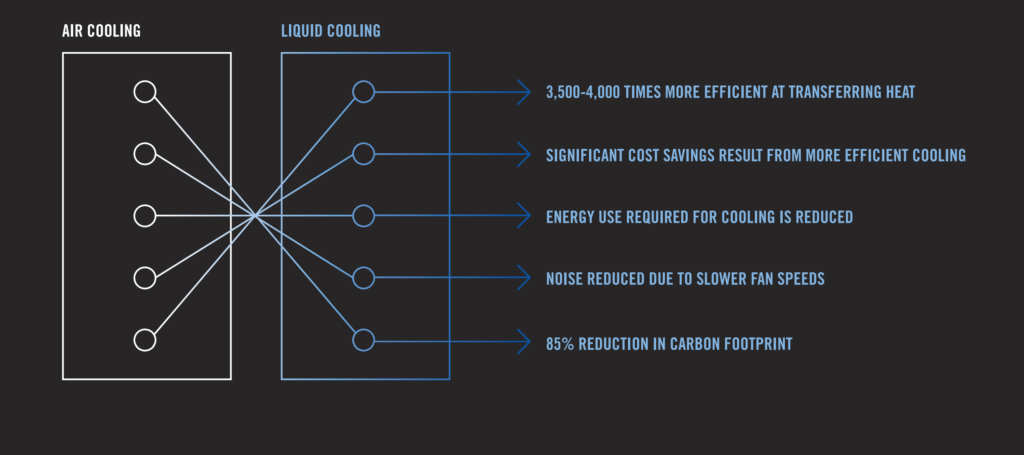

Liquid Cooling: It's Simple Physics.

Data centers around the world are being tasked with the challenge of increasing energy efficiency, consolidating operations and reducing costs. The fundamental nature of liquid cooling provides a powerful tool to start addressing those challenges head-on and it will be a key factor in moving the power usage effectiveness (PUE) of data centers closer to 1.0.