- info@pennair.com

- 888-631-7638

- Service Counter: 717-840-1600

August 30, 2021 // 1 minute read

Dorner’s customized packaging solutions offer increased flexibility for elevated production with decreased waste. These solutions can keep your business’ production flowing quickly and seamlessly, at maximum efficiency.

Dorner packaging conveyors’ modular design is ideal for any industry application and will support your business’ future needs. Our solutions can help control product flow with the ability to merge, divert, route and pace movement.

Dorner offers several different lines of packaging conveyor systems to accommodate any product your business might have. Dorner packaging conveyor applications provide your business with the ability to optimize labor assets while achieving accurate, consistent and safe product routing while reducing product loss.

Dorner conveyors are widely used by packaging companies in a wide range of industries such as the metalworking, material-handling, and manufacturing industries along with those connected to other non-consumable products.

Our experts are trained in designing the best custom conveyor for all your business’ needs using a wide variety of our conveyor products, including:

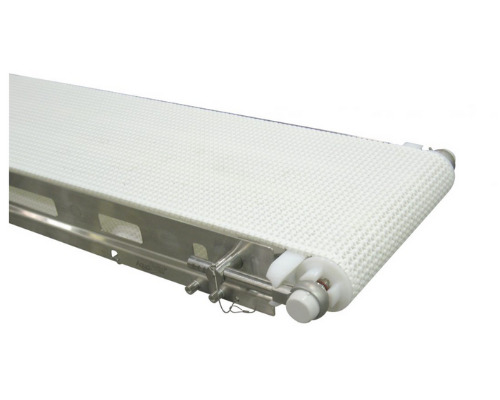

Dorner’s 2200 Series Conveyors feature low-profile, high-performance fabric and modular belt conveyors with a high-speed nose bar transfer option, durable single-piece frame design, universal T-slots and range of belting and guiding options.

Our 2200 Series Conveyors are best for:

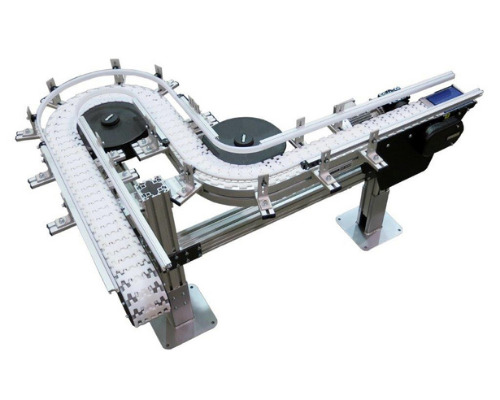

Dorner’s FlexMove Conveyors offer many options with unique features such as a flexible chain with cleats, rollers, friction pads, steel top and anti-static and fabric belts.

Our FlexMove Conveyors are best for:

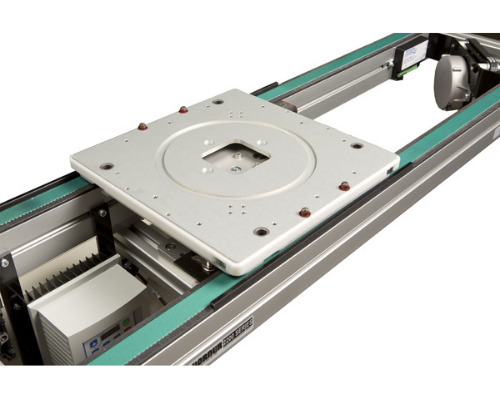

Dorner’s 3200 Series Conveyors come with the industry’s leading V-guiding, providing positive belt tracking under demanding side load applications. These conveyors’ modular belts and spliced standard belts help reduce downtime by enabling quick and easy belt changing.

Our 3200 Series Conveyors are best for:

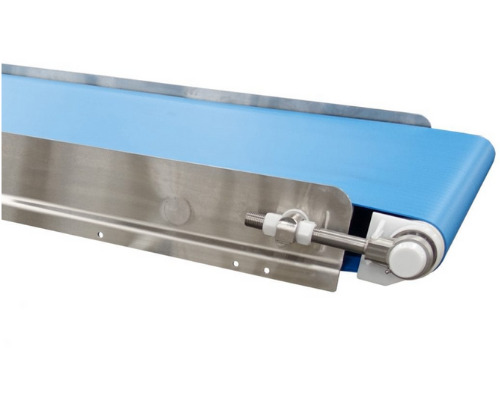

Dorner’s AquaGard Conveyors raise food-handling conveyors to a whole new level. Built for fast and effective sanitation as well as protection from contamination, our AquaGard Conveyors deliver the same Dorner quality and flexible designs as our customers have come to expect in all our systems.

Our AquaGard Conveyors are best for:

We’re looking forward to helping you. Whether you have questions about products, services, or a demo, our team is ready to help.

Fields with an asterisk* are required. This information allows us to better assist you.

Your information will not be shared beyond our organization. The information collected is simply used to better assist you. Please visit our Privacy Policy to learn more.

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/