National Food Safety Month began in September 1994 to heighten awareness of the foodborne illness, and to educate on how to prevent it. The Federal government estimates that there are about 48 million cases of foodborne illness a year. As the food market continues to globalize and our population grows, the food supply chain increases in scale. The production and distribution of food and food safety are at an all-time high. To sell or manufacture food products in any given country, domestic and international businesses are subject to the food safety legislation and enforcement measures of that nation

Tag: food safety

Conveyor Solution for Disposal of Lettuce Scraps

The Urban Farming industry very demanding environment for any conveyor, much less one that’s specifically designed to work in these conditions. That’s because of the tremendous amount of debris collected on the conveyor from the discarded produce and dirt debris. So the conveyor system needs to be durable for continuous use, yet designed for daily wash downs. Dorner offers the perfect conveyor to meet the demands of the Urban Farmer.

Conveyors for Food Handling and Processing

Dorner’s world-class food handling and processing conveyors are highly sanitary and built to operate at fast speeds. These conveyors have earned a stellar track record in helping businesses maximize their efficiency and productivity levels in achieving their full potential. If your business requires custom food processing equipment, PennAir & Dorner are uniquely positioned to develop specially made conveyors that meet our customers’ vision for enhanced workflow.

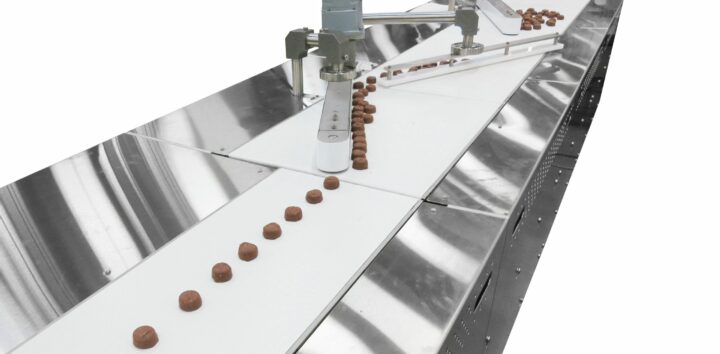

Dorner Chicaning Conveyors

The purpose of chicaning conveyor system is to take random, misaligned or grouped products and spread them into a single file line. In certain production processes, products are grouped together. This can occur either on purpose or as a result of the process such as in an oven, where product needs be spread out to allow for even baking. However, further down the line the product needs to be reoriented or placed in specific rows and spacing. The challenge is how to take randomly spread product and create neat rows with spacing.

Conveyors Designed for the Cheese & Dairy Industry

PennAir partners with Dorner Conveyors to deliver a line of conveyors designed to meet the strict requirements of USDA Dairy regulations and 3-A Sanitary Standards. We have experience handling a variety of dairy products such as: cheese slices, cheese blocks, mozzarella balls, bulk cheese shreds, brine tank extractions and more. With our range of expertise, Dorner can custom design a system to meet your unique need.

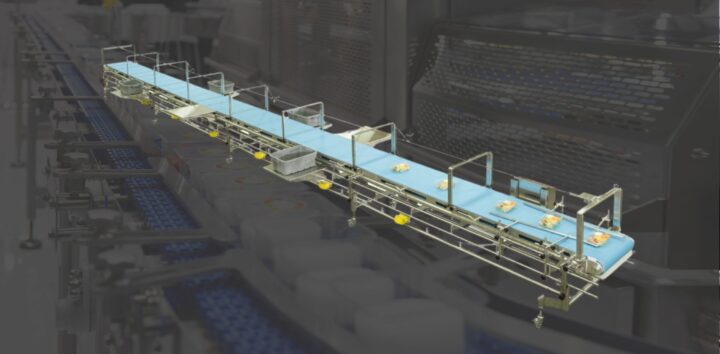

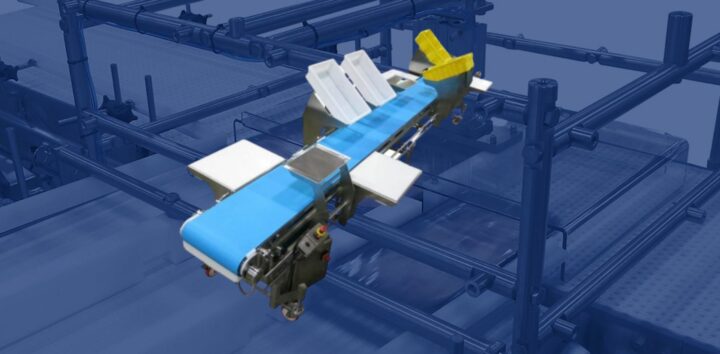

Ready-to-Eat Conveyors for Consumer Industry

PennAir partners with Dorner Conveyors to deliver kick@$$ conveying solutions for ready-to-eat foods. Dorner has experience with ready-to-eat foods such as sandwiches, meals, parfait cups, salads and more. They understand that these produces require conveyors that can be efficiently and effectively cleaned and sanitized over the lifetime of the equipment. Also, all parts of the… equipment…

Conveyors Designed for Food Safety

Food safety is always an important issue when it comes to meat, poultry and all types of food processing. Dorner’s sanitary conveyors are designed with the safety of your product, customers and employees in mind.

With new risks for processing employees due to COVID-19, employee safety is now more important than ever. It is necessary to have processing equipment that allows you to keep your operation running while keeping your employees safely distanced.

In the winter, however, temperatures may drop well below 40 degrees Fahrenheit and remain low for long periods of time.