When conveying products in the pharmaceutical and nutraceutical industries, accuracy and safety are vital. Dorner’s line of precision and sanitary conveyors are designed to meet these needs. When conveying products in the pharmaceutical and nutraceutical industries, accuracy and safety are vital. Dorner’s line of precision and sanitary conveyors are designed to meet these needs. When conveying products in the pharmaceutical and nutraceutical industries, accuracy and safety are vital. Dorner’s tote systems can automate processes and increase efficiencies for pharmacies. See examples of tote systems we have created using 2200 Series conveyors and our FlexMove conveyors.

Tag: dorner

Dorner Medical Industry

Gentle flow, self-clearing spiral chutes for lowering products from high elevations. Gently and economically lower products from overhead conveyors, mezzanines or platforms. Patent pending “stair step” design ensures products won’t get stuck, even when accumulated. Durable, bolt-together construction

Ideal for light weight packages

Capable of handling a variety of package types including cardboard, pouches, flexible packaging, corrugated boxes, and more! Capable of handling different products at the same time. Ships assembled for fast and simple installation.

Dorner Spiral Chute Conveyors

Gentle flow, self-clearing spiral chutes for lowering products from high elevations.

Gently and economically lower products from overhead conveyors, mezzanines or platforms.

Patent pending “stair step” design ensures products won’t get stuck, even when accumulated

Durable, bolt-together construction

Ideal for light weight packages

Capable of handling a variety of package types including cardboard, pouches, flexible packaging, corrugated boxes, and more!

Capable of handling different products at the same time

Ships assembled for fast and simple installation

Dorner Integrators

PennAir offers Dorner Precision Move conveyors in their 2200 and 3200 series lines which are a great way to make sure that your product gets to the right spot at the right time. These conveyors offer accurate alignment every time, making them ideal for applications that require precision. Features on the Precision Move include: Cogged belt and side guides to ensure excellent belt tracking

Speeds of up to 370 ft/min

Optional pallet mounting bars for product transportation and handling

Conveyor Solution for Disposal of Lettuce Scraps

The Urban Farming industry very demanding environment for any conveyor, much less one that’s specifically designed to work in these conditions. That’s because of the tremendous amount of debris collected on the conveyor from the discarded produce and dirt debris. So the conveyor system needs to be durable for continuous use, yet designed for daily wash downs. Dorner offers the perfect conveyor to meet the demands of the Urban Farmer.

Conveyors for Food Handling and Processing

Dorner’s world-class food handling and processing conveyors are highly sanitary and built to operate at fast speeds. These conveyors have earned a stellar track record in helping businesses maximize their efficiency and productivity levels in achieving their full potential. If your business requires custom food processing equipment, PennAir & Dorner are uniquely positioned to develop specially made conveyors that meet our customers’ vision for enhanced workflow.

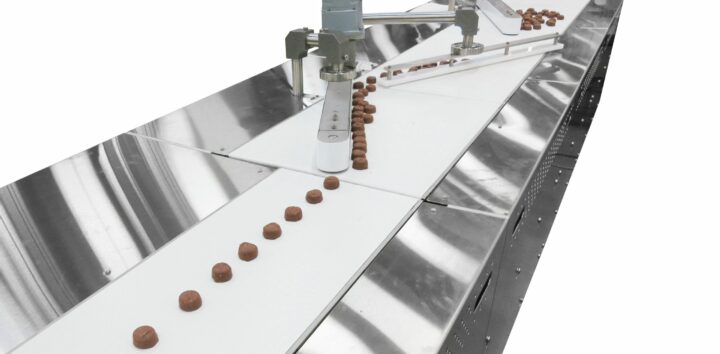

Dorner Chicaning Conveyors

The purpose of chicaning conveyor system is to take random, misaligned or grouped products and spread them into a single file line. In certain production processes, products are grouped together. This can occur either on purpose or as a result of the process such as in an oven, where product needs be spread out to allow for even baking. However, further down the line the product needs to be reoriented or placed in specific rows and spacing. The challenge is how to take randomly spread product and create neat rows with spacing.