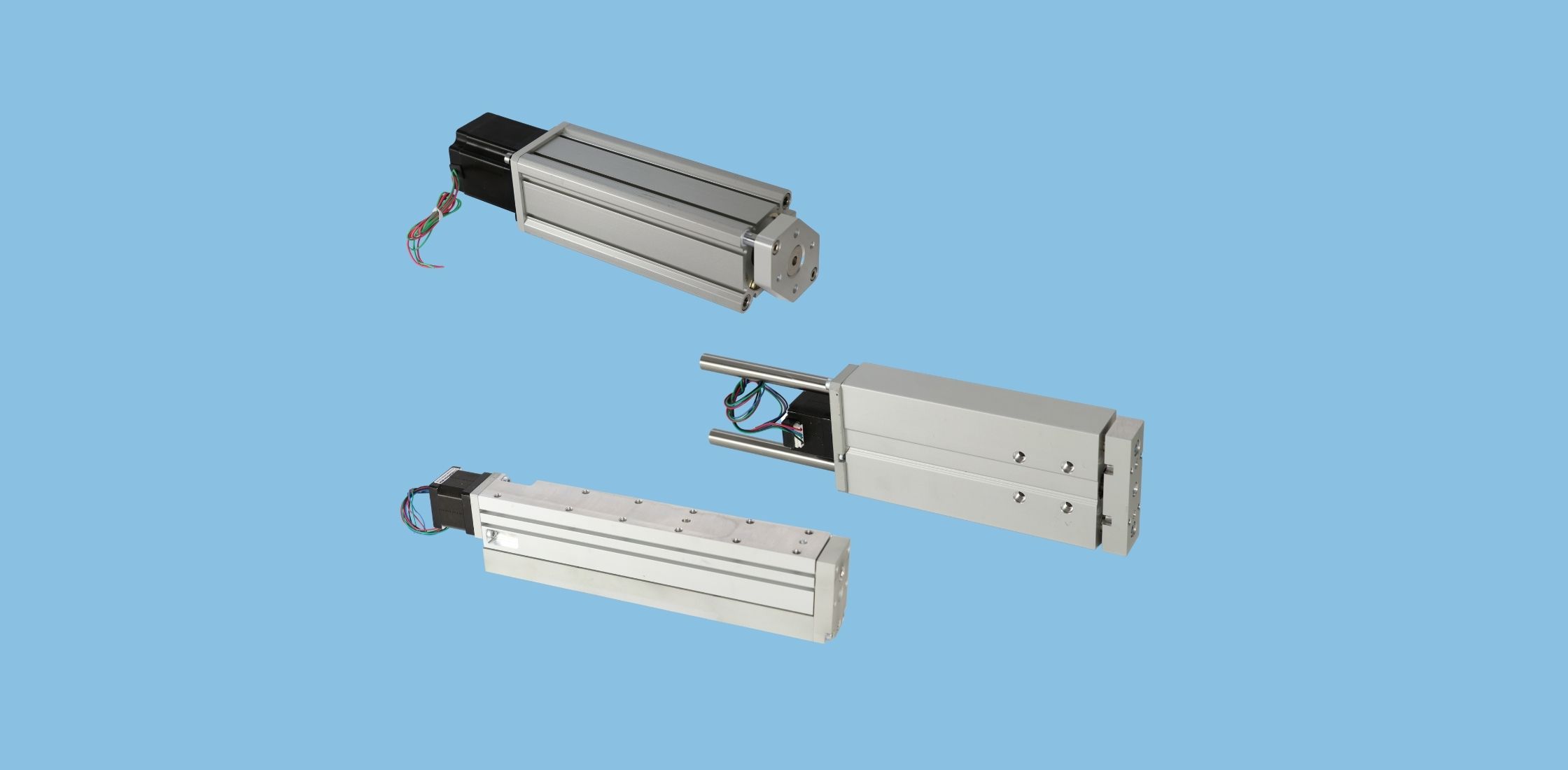

PennAir partners with Norgren to offer a NEW compact guided electric actuators are designed with a similar size, construction, and body of a pneumatic actuator in order to accommodate tight spaces for a diverse range of applications. These actuators are based on simplifying converting a pneumatic application to electric motion. With multiple screw and...

Read More

- info@pennair.com

- 888-631-7638

- Service Counter: 717-840-1600