Enidine offers the broadest range of small bore adjustable and non-adjustable industrial shock absorbers and mounting accessories in the marketplace today.

Tag: food processing

Dorner Conveyors for Food Handling & Processing

At Dorner, we believe food safety is paramount. We understand the concerns and challenges facing teams in the food handling industry. Whether your food needs are in bakery and confectionary; dairy and cheese; ready-to-eat foods; meat, poultry and seafood, fruits and vegetables; or any other foods, our AquaPruf Series conveying system can meet your needs.

Dorner can also provide the following conveyor accessory add-ons:

Belt scrapers

Guiding

Conveyor covers

Chutes

Drip pans

Deviators

Automated controls

Food Safety Month

National Food Safety Month began in September 1994 to heighten awareness of the foodborne illness, and to educate on how to prevent it. The Federal government estimates that there are about 48 million cases of foodborne illness a year. As the food market continues to globalize and our population grows, the food supply chain increases in scale. The production and distribution of food and food safety are at an all-time high. To sell or manufacture food products in any given country, domestic and international businesses are subject to the food safety legislation and enforcement measures of that nation

Dorner AquaPruf Conveyors

Frame is designed with no horizontal surfaces for optimum cleaning. Conveyors over 10′ long consist of multiple sections which are bolted together. Bearings are mounted in cast stainless steel housing for maximum performance in washdown environments. Solid UHMW wear strips are easily lifted out of the frame without tools to minimize cleaning time. The tool-less tip-up pulley allows the conveyor end to be lifted easily for quick access to inside of conveyor for cleaning.

Conveyor is designed to withstand high pressure (100-1,500 psi) spray and chlorinated cleaning solutions.

The return belt supports are segmented plastic slide blocks and are easily removed without tools for effective cleaning.

Dorner Conveyors for the Packaging Industry

Dorner’s customized packaging solutions offer increased flexibility for elevated production with decreased waste. These solutions can keep your business’ production flowing quickly and seamlessly, at maximum efficiency.

Dorner packaging conveyors’ modular design is ideal for any industry application and will support your business’ future needs. Our solutions can help control product flow with the ability to merge, divert, route and pace movement.

DORNER EDGE ROLLER TECHNOLOGY CONVEYORS

Our precision edge roller pallet and tray handling conveyors provide efficient, non-contact zoning for medium & heavy load assembly automation applications. They feature a clean, open roller design and are ISO Class 4 approved for cleanrooms. Pallet & tray handling

No & low back pressure accumulation

Cleanroom applications

Large & medium assembly automation

Medical Product Manufacturing

Packaging

Medical Device Manufacturing

Automotive Assembly

Electronic & Consumer Goods Assembly

Appliance Manufacturing

Conveyor Solution for Disposal of Lettuce Scraps

The Urban Farming industry very demanding environment for any conveyor, much less one that’s specifically designed to work in these conditions. That’s because of the tremendous amount of debris collected on the conveyor from the discarded produce and dirt debris. So the conveyor system needs to be durable for continuous use, yet designed for daily wash downs. Dorner offers the perfect conveyor to meet the demands of the Urban Farmer.

Conveyors for Food Handling and Processing

Dorner’s world-class food handling and processing conveyors are highly sanitary and built to operate at fast speeds. These conveyors have earned a stellar track record in helping businesses maximize their efficiency and productivity levels in achieving their full potential. If your business requires custom food processing equipment, PennAir & Dorner are uniquely positioned to develop specially made conveyors that meet our customers’ vision for enhanced workflow.

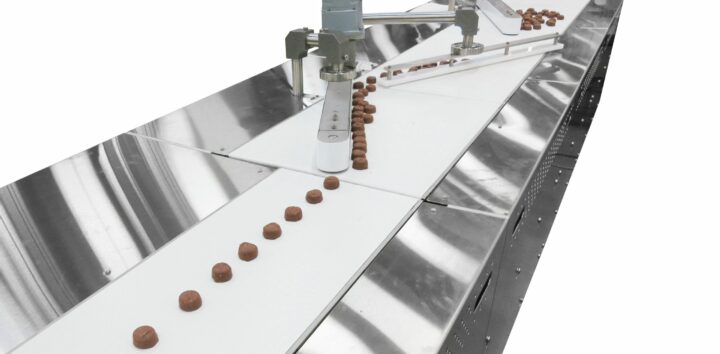

Dorner Chicaning Conveyors

The purpose of chicaning conveyor system is to take random, misaligned or grouped products and spread them into a single file line. In certain production processes, products are grouped together. This can occur either on purpose or as a result of the process such as in an oven, where product needs be spread out to allow for even baking. However, further down the line the product needs to be reoriented or placed in specific rows and spacing. The challenge is how to take randomly spread product and create neat rows with spacing.